In the rapidly evolving world of laboratory and pharmaceutical research, environmental control has become more critical than ever. Among the most significant innovations in lab infrastructure are pharmaceutical dehumidification dry rooms. These specialized environments, designed to maintain precise humidity levels, are revolutionizing how labs conduct sensitive research and manufacture pharmaceutical products. Pharmaceutical dehumidification dry rooms manufacturers are at the forefront of this transformation, providing solutions that ensure accuracy, safety, and compliance with stringent industry standards.

The Importance of Controlled Environments in Modern Laboratories

Laboratories today face increasing demands for precision, repeatability, and adherence to regulatory standards. Many pharmaceutical compounds and sensitive materials are hygroscopic, meaning they absorb moisture from the air. Even slight fluctuations in humidity can compromise the integrity of experiments, reduce the shelf life of products, and affect analytical results. Pharmaceutical dehumidification dry rooms are engineered to mitigate these risks by maintaining extremely low and stable humidity levels.

Pharmaceutical dehumidification dry rooms manufacturers are responsible for designing systems that can achieve and sustain these conditions. Their expertise lies in understanding both the chemical properties of substances used in laboratories and the mechanical requirements needed to control environmental factors. By integrating advanced sensors, airflow management systems, and precision dehumidification technologies, these manufacturers ensure labs can operate without the interference of uncontrolled moisture.

Key Technologies Driving Pharmaceutical Dehumidification

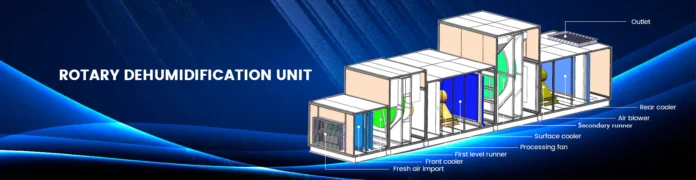

Modern pharmaceutical dehumidification dry rooms rely on sophisticated technologies to maintain optimal conditions. These include desiccant dehumidifiers, refrigeration-based systems, and hybrid solutions that combine multiple methods for maximum efficiency. Desiccant dehumidifiers, for example, use moisture-absorbing materials to remove water vapor from the air, achieving extremely low humidity levels ideal for sensitive pharmaceutical processes.

Refrigeration-based dehumidifiers, on the other hand, condense moisture by cooling the air, effectively reducing humidity in larger lab spaces. Many pharmaceutical dehumidification dry rooms manufacturers now offer hybrid systems that combine both approaches, allowing laboratories to achieve precise control over humidity, temperature, and airflow simultaneously. This integration ensures that pharmaceutical development, research, and manufacturing can occur in a stable and controlled environment, minimizing the risk of contamination or product degradation.

Customization and Compliance

One of the hallmarks of pharmaceutical dehumidification dry rooms manufacturers is their ability to provide customized solutions. Not all laboratories have the same requirements, and pharmaceutical production often involves highly specialized processes. Manufacturers assess the specific needs of each lab, including space dimensions, humidity tolerances, and workflow patterns, to design a dry room that meets exact specifications.

Regulatory compliance is another critical factor driving the demand for these systems. Pharmaceutical labs must adhere to Good Manufacturing Practices (GMP) and other international standards. By working closely with pharmaceutical dehumidification dry rooms manufacturers, labs can ensure that their facilities not only meet these requirements but exceed them. Manufacturers provide documentation, validation protocols, and installation support, giving laboratories confidence that their controlled environments are compliant and reliable.

Enhancing Productivity and Reducing Costs

Beyond compliance and precision, pharmaceutical dehumidification dry rooms manufacturers are shaping the economics of modern labs. Controlled humidity environments reduce the likelihood of product loss due to moisture-related degradation. This translates into significant cost savings, especially when handling high-value pharmaceuticals or rare compounds.

Moreover, these dry rooms improve operational efficiency. Laboratories can conduct longer experiments, store sensitive materials safely, and avoid delays caused by environmental instability. Pharmaceutical dehumidification dry rooms manufacturers contribute to this efficiency by designing systems that are energy-efficient, easy to maintain, and scalable, ensuring that labs can adapt to growing research demands without extensive infrastructure overhauls.

Driving Innovation in Pharmaceutical Research

The impact of pharmaceutical dehumidification dry rooms extends beyond operational efficiency. By providing controlled environments, manufacturers enable researchers to explore new drug formulations, advanced delivery systems, and sensitive biologics that would otherwise be impossible under fluctuating humidity conditions. This capability is particularly important in the development of moisture-sensitive drugs such as antibiotics, peptides, and vaccines.

Pharmaceutical dehumidification dry rooms manufacturers often collaborate with labs during the research phase, providing guidance on environmental requirements for novel compounds. This partnership helps accelerate innovation, reduce trial-and-error testing, and improve overall research outcomes. As a result, the industry sees faster time-to-market for new therapies and higher confidence in product stability and safety.

Trends Shaping the Future of Dry Room Manufacturing

The future of pharmaceutical dehumidification dry rooms is being shaped by advances in automation, IoT integration, and data-driven environmental control. Modern systems now feature remote monitoring, predictive maintenance, and real-time analytics, allowing lab managers to optimize humidity and temperature conditions continuously.

Pharmaceutical dehumidification dry rooms manufacturers are increasingly incorporating these smart technologies into their designs. Sensors connected to cloud platforms provide continuous feedback, alerting staff to deviations before they impact experiments or production. This trend not only enhances reliability but also provides a wealth of data that can be used for quality control, process optimization, and regulatory reporting.

Sustainability is another emerging trend. Manufacturers are designing dry rooms that consume less energy, reduce water usage, and use environmentally friendly refrigerants, aligning with global initiatives for greener laboratory operations.

Conclusion

Pharmaceutical dehumidification dry rooms manufacturers play a pivotal role in shaping the future of modern laboratories. Their expertise in designing, building, and maintaining controlled environments ensures that labs can operate with precision, efficiency, and compliance. By providing customized solutions, integrating advanced technologies, and supporting innovation, these manufacturers are not just building rooms—they are enabling breakthroughs in pharmaceutical research and production.

As laboratories continue to evolve and the demand for high-quality, moisture-sensitive products grows, the role of pharmaceutical dehumidification dry rooms manufacturers will become increasingly central. Their contributions ensure that research is reliable, production is safe, and the next generation of pharmaceutical advancements can thrive in an environment built for success.