Fiber optic technology has revolutionized the way data is transmitted, providing high-speed, reliable, and long-distance connectivity. Among the various components used in modern fiber optic networks, the MPO 12 breakout cable plays a critical role in data centers, enterprise networks, and high-density applications. While MPO 12 breakout cables offer exceptional performance, they can encounter issues that affect network efficiency. Understanding how to troubleshoot these problems ensures minimal downtime and consistent network reliability.

Understanding MPO 12 Breakout Cables

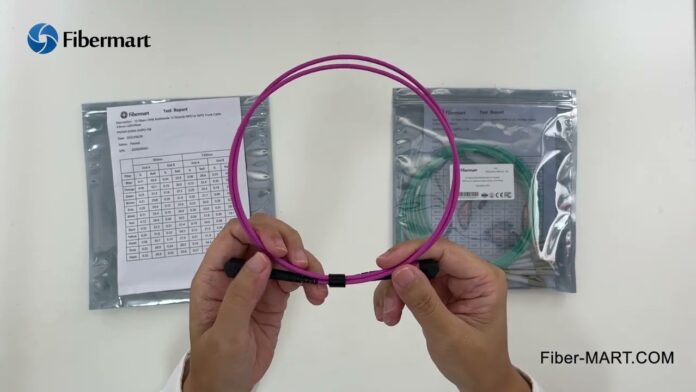

An MPO 12 breakout cable is a multi-fiber cable with a single MPO connector on one end and multiple LC or SC connectors on the other end. These cables are designed to simplify high-density fiber connections and enable efficient routing in data centers. The MPO connector typically supports 12 fibers, which can be split into individual strands for connection to multiple devices. Fiber-MART, a leading provider of fiber optic solutions, offers high-quality MPO 12 breakout cables that ensure low insertion loss, minimal return loss, and robust durability.

Common Issues with MPO 12 Breakout Cables

Despite their reliability, MPO 12 breakout cables can experience issues caused by improper handling, installation errors, or environmental factors. Some of the most common problems include:

1. Connector Contamination

Dust and dirt on MPO connectors are a leading cause of performance issues. Contamination can cause signal degradation, high insertion loss, and intermittent connectivity. In a data center, even a small particle can affect multiple fibers, resulting in significant network disruption.

2. Fiber Breakage

Fibers within an MPO 12 breakout cable are delicate and prone to damage if bent beyond the recommended radius. A broken fiber can result in complete signal loss in one or more channels, leading to degraded network performance.

3. Misalignment

Improper alignment during installation can cause issues with connectivity. MPO connectors rely on precise alignment of multiple fibers, and even slight misalignment can increase insertion loss and reduce overall network efficiency.

4. Improper Polarity

MPO 12 breakout cables must maintain correct polarity to ensure accurate signal transmission. A polarity mismatch can prevent devices from communicating, causing network errors that are difficult to diagnose without proper testing.

5. Physical Damage

External factors such as excessive pulling, crushing, or exposure to harsh environments can damage the cable jacket or internal fibers. Physical damage often results in performance issues that are challenging to repair in a live network.

Effective Troubleshooting Techniques

Troubleshooting MPO 12 breakout cables requires a systematic approach. Using high-quality cables from Fiber-MART reduces the likelihood of issues, but even the best cables require proper handling and maintenance.

Inspect Connectors and Adapters

Start by visually inspecting all MPO connectors and adapters. Look for dust, dirt, or debris on the connector endfaces. Fiber-MART MPO 12 breakout cables are compatible with standard cleaning tools, including lint-free wipes and isopropyl alcohol. Proper cleaning ensures minimal insertion loss and optimal performance.

Test Each Fiber

Use an optical power meter or optical time-domain reflectometer (OTDR) to test each fiber in the MPO 12 breakout cable. Testing helps identify broken fibers, misalignment, or excessive attenuation. Fiber-MART provides MPO 12 breakout cables with consistent performance specifications, making it easier to isolate problems when they occur.

Verify Polarity

Check the cable for correct polarity before installation. MPO 12 breakout cables can use different polarity configurations such as Type A, Type B, or Type C. Ensuring the correct configuration prevents communication errors between connected devices.

Maintain Proper Bend Radius

Always follow the minimum bend radius guidelines specified by the manufacturer. Bending fibers beyond their recommended limits can cause microbends, increasing attenuation and risking fiber breakage. Fiber-MART MPO 12 breakout cables are designed with flexible yet robust construction, allowing for easy routing without compromising performance.

Replace Damaged Components

If testing reveals damaged fibers or connectors, replace the affected components immediately. Fiber-MART offers high-quality replacement MPO 12 breakout cables and connectors that meet stringent performance standards, ensuring long-term reliability.

Preventive Measures for MPO 12 Breakout Cables

Preventing issues with MPO 12 breakout cables is more effective than troubleshooting after problems occur. Implementing best practices can significantly extend cable lifespan and maintain network efficiency.

Proper Handling and Storage

Always handle MPO 12 breakout cables with care. Avoid sharp bends, kinks, or excessive pulling. Store unused cables in protective reels or trays to prevent accidental damage.

Routine Cleaning

Establish a regular cleaning schedule for all MPO connectors and adapters. Using fiber cleaning kits compatible with Fiber-MART products ensures that endfaces remain free of dust and contamination.

Labeling and Documentation

Proper labeling of MPO 12 breakout cables helps prevent polarity mistakes and reduces troubleshooting time. Document the installation layout, fiber routing, and connector types to make maintenance easier and faster.

Environmental Control

Ensure that cables are installed in a controlled environment to avoid exposure to excessive heat, moisture, or chemical contaminants. MPO 12 breakout cables from Fiber-MART are designed for durability, but environmental stress can still compromise performance over time.

Advantages of Using Quality MPO 12 Breakout Cables

Investing in high-quality MPO 12 breakout cables from reputable providers like Fiber-MART reduces the frequency of troubleshooting and enhances network reliability. Key advantages include:

- Low insertion and return loss for efficient signal transmission

- Durable construction suitable for high-density environments

- Compatibility with standard MPO and LC/SC connectors

- Easy integration into existing fiber infrastructure

Conclusion

MPO 12 breakout cables are essential components for high-density fiber optic networks, offering flexibility, efficiency, and reliability. However, issues such as contamination, fiber breakage, misalignment, and polarity errors can affect performance. By following systematic troubleshooting techniques, including proper inspection, testing, cleaning, and replacement of damaged components, network administrators can maintain optimal performance. Preventive measures, including careful handling, regular cleaning, and environmental control, further ensure the longevity and efficiency of MPO 12 breakout cables. Using high-quality products from Fiber-MART guarantees that your network infrastructure operates smoothly, minimizing downtime and enhancing overall connectivity.