In modern woodworking and furniture manufacturing, clean finishes and professional-quality edges are no longer optional—they are expected. This is where the Edge Banding Machine becomes an indispensable tool. Designed to apply thin strips of material to exposed panel edges, this machine enhances durability, appearance, and overall product value. Whether you run a small workshop or a large-scale production facility, understanding how an Edge Banding Machine works and what features matter most can help you make smarter decisions and improve efficiency.

Understanding What an Edge Banding Machine Is

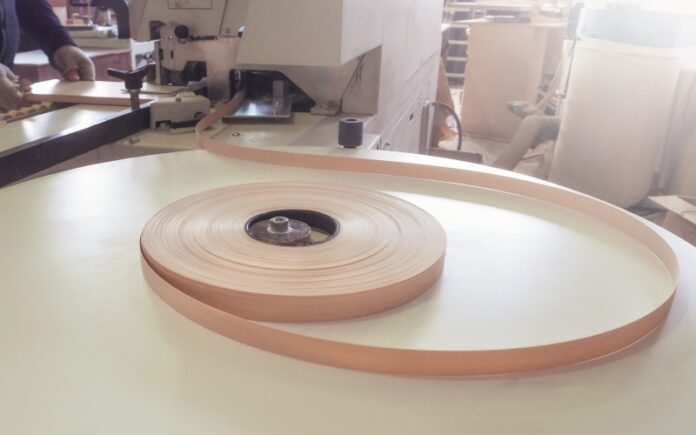

An Edge Banding Machine is a specialized woodworking machine used to cover the raw edges of panels such as plywood, MDF, particleboard, or solid wood. These raw edges are vulnerable to moisture, impact, and wear. By applying edge banding materials like PVC, ABS, veneer, or wood strips, the machine seals and protects the panel while giving it a seamless, finished look.

This process is essential in the production of cabinets, wardrobes, office furniture, kitchen units, and custom wood projects. Manual edge banding methods still exist, but automated and semi-automatic machines have become the industry standard due to speed, precision, and consistency.

Why Edge Banding Is Important in Woodworking

Edge banding plays a critical role in both functionality and aesthetics. From a practical standpoint, it prevents moisture penetration and reduces chipping or cracking along panel edges. From a visual perspective, edge banding makes furniture look refined and complete, closely resembling solid wood construction.

Using an Edge Banding Machine ensures uniform application, strong adhesion, and smooth trimming, which are difficult to achieve consistently by hand. This results in higher-quality output and fewer rejected pieces during production.

Types of Edge Banding Machines

Edge Banding Machines come in various configurations to suit different production needs and budgets.

Manual Edge Banding Machines

Manual machines are ideal for small workshops and low-volume production. Operators feed the panel and apply pressure manually while the machine handles glue application and banding. These machines are cost-effective but require more operator skill and time.

Semi-Automatic Edge Banding Machines

Semi-automatic machines strike a balance between affordability and efficiency. They automate most processes such as glue application and trimming, while the operator controls panel feeding. These machines are popular among medium-sized workshops.

Automatic Edge Banding Machines

Automatic Edge Banding Machines are designed for high-volume industrial use. They handle every step of the process automatically, from panel feeding to final polishing. These machines offer unmatched speed, accuracy, and consistency, making them ideal for mass production environments.

Key Features of an Edge Banding Machine

Understanding the main features of an Edge Banding Machine helps you choose the right model and maximize its potential.

Glue Application System

The glue system is the heart of any Edge Banding Machine. It heats and applies adhesive evenly to ensure strong bonding between the panel and edge banding material. Modern machines often use EVA or PUR glue systems, with PUR offering superior moisture resistance and durability.

Edge Banding Material Feeding

This feature controls how the banding material is fed and pressed onto the panel edge. Precision feeding ensures uniform coverage and prevents gaps or misalignment. Advanced machines can handle different thicknesses and materials without extensive adjustments.

End Cutting Unit

Once the edge banding is applied, the excess material at the front and back of the panel must be trimmed. The end cutting unit performs this task cleanly, ensuring flush edges and sharp corners.

Top and Bottom Trimming

Top and bottom trimming units remove excess edge banding material along the length of the panel. This step is essential for achieving a smooth, even surface that aligns perfectly with the panel face.

Scraping and Buffing Units

Scraping units refine the edge by removing fine imperfections, while buffing units polish the surface for a glossy, professional finish. These final steps significantly enhance the visual quality of the finished product.

Functions That Enhance Productivity

Beyond basic edge banding, modern Edge Banding Machines offer advanced functions that improve efficiency and flexibility.

Adjustable Speed Control

Speed control allows operators to adjust feed rates based on material type and complexity. Slower speeds improve precision for delicate materials, while higher speeds boost output for standard production runs.

Digital Control Panels

Many machines now feature digital interfaces that allow precise control over temperature, pressure, and speed. These panels simplify operation, reduce setup time, and minimize human error.

Quick Change Systems

Quick change systems make it easier to switch between different edge banding materials or thicknesses. This is especially useful for workshops handling custom or varied projects.

Choosing the Right Edge Banding Machine

Selecting the right Edge Banding Machine depends on several factors, including production volume, material types, and budget.

Workshop Size and Production Needs

Small workshops may benefit from manual or semi-automatic machines, while large manufacturers typically require fully automatic systems. Matching machine capacity to your workload prevents unnecessary expenses and downtime.

Material Compatibility

Ensure the machine supports the edge banding materials you plan to use. Not all machines handle thick PVC or solid wood edges equally well, so compatibility is crucial.

Maintenance and Support

Reliable after-sales support and easy maintenance are important considerations. A machine with readily available spare parts and clear maintenance procedures will save time and money in the long run.

Benefits of Using an Edge Banding Machine

Investing in an Edge Banding Machine offers numerous advantages for woodworking professionals.

Improved Product Quality

Consistent edge finishes elevate the overall appearance and durability of furniture and panels, meeting higher customer expectations.

Increased Efficiency

Automated processes significantly reduce production time compared to manual methods, allowing workshops to handle larger orders without compromising quality.

Cost Savings Over Time

Although the initial investment may be significant, reduced labor costs, fewer errors, and less material waste make Edge Banding Machines cost-effective in the long term.

Future Trends in Edge Banding Technology

The woodworking industry continues to evolve, and Edge Banding Machines are no exception. Innovations such as laser edge banding, zero-joint technology, and smart automation are becoming more common. These advancements further improve finish quality and reduce adhesive visibility, pushing the boundaries of what is possible in panel processing.

Conclusion

An Edge Banding Machine is a vital asset for anyone involved in modern woodworking or furniture production. By understanding its features, functions, and benefits, you can select the right machine to match your needs and elevate the quality of your work. From basic edge protection to advanced finishing solutions, the Edge Banding Machine remains a cornerstone of efficient, professional, and competitive woodworking operations.